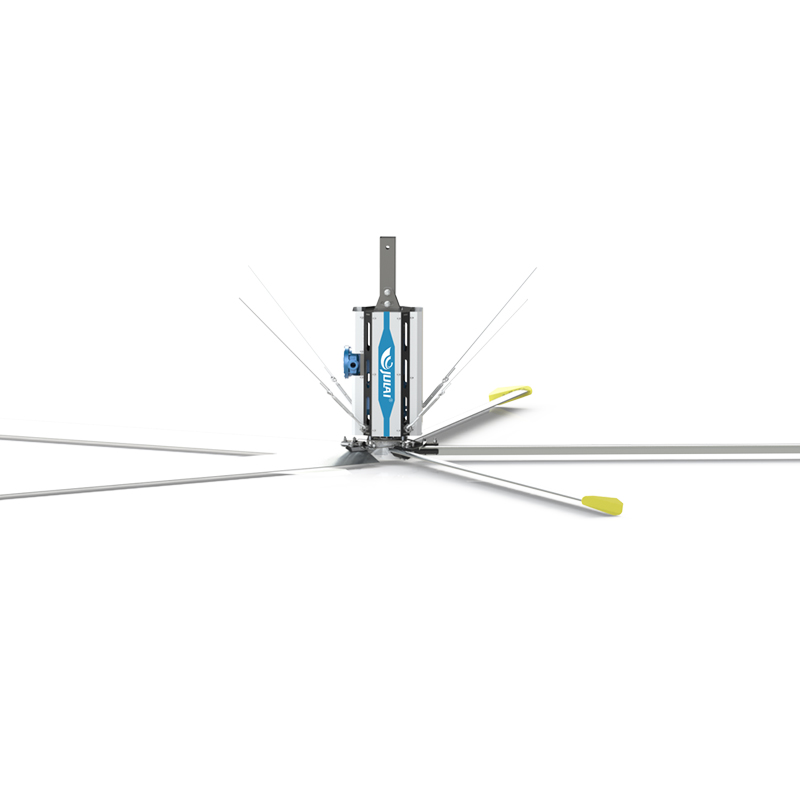

In our lives, Industrial Fans are widely used in large spaces such as industrial plants, logistics warehouses, outdoor sports fields, commercial centers, stations, and livestock farms. What causes Industrial Fans noise? In response to this problem, let`s take a look at the reasons why Industrial Fans are noisy.

1. Industrial Fans wind noise: When an Industrial Fans is working, the blades periodically bear the uneven pulse force of the outlet airflow, causing noise; on the other hand, due to the uneven pressure distribution on the blades themselves and on the blades, the surrounding gas and Disturbance of parts also constitutes rotational noise. In addition, due to the turbulent boundary layer, vortices and eddy separation when the gas flows through the blades, the pressure distribution on the blades fluctuates, producing eddy noise. The noise caused by these three reasons can be comprehensively called "cutting noise". Generally,

Industrial Ceiling Fan with large air volume and pressure will also have larger cutting noise.

2. At present, some Industrial Ceiling Fan manufacturers on the market use cheap materials for the blades in order to save costs, and the manufacturing process is not up to standard, resulting in "eccentricity". After an Industrial Ceiling Fan has been running for a period of time, the "eccentricity" will become more and more serious and noise will gradually occur, which needs to be solved by the company itself when purchasing Industrial Fans.

3. Industrial Fans vibration: Assuming that when the Industrial Fans rotor rotates, the physical center of mass of the rotor and the center of inertia of the rotating shaft are not on the same axis, it will cause imbalance of the rotor. The closest distance between the physical center of mass of the rotor and the center of inertia of the rotating shaft is called eccentricity. Unbalanced rotor causes eccentricity. When the rotor rotates, a force acts on the shaft support due to centrifugal force, and vibrations are transmitted through the base path to all parts of the machine.

4. Industrial Fans abnormal noise: Wind noise sounds like pure wind sound, but abnormal noise is different. When the Industrial Fans is running, in addition to the wind sound, if there are other sounds, it can be judged that the Industrial Fans has abnormal noise. Abnormal noise may be caused by foreign matter or deformation in the bearing, collision due to improper assembly, or uneven winding of the motor winding, resulting in looseness, which may cause abnormal noise.

5. After long-term operation of Industrial Fans, the noise caused by the lack of lubricating oil in the bearings can only be solved by dripping lubricating oil.

6. During the long-term operation of Industrial Ceiling Fan, the shock-absorbing pads between the blades and petioles wear out, and noise will be generated when there are gaps. At this time, we only need to replace the shock pad and tighten the screws to solve the problem.

7. The higher the voltage of the Industrial Fans, the higher the speed, the greater the vibration, and the greater the noise. The design of Industrial Ceiling Fan components can also affect noise levels. At this point we only need to consider the size of the core, the design of the blades and outer frame, as well as manufacturing and balancing.